Ground Support Equipment (GSE) is vital for airport operations, and the TLD transporter plays a key role in moving baggage and cargo. But sometimes, this machine may suddenly stop moving, causing major delays.

Table of Contents

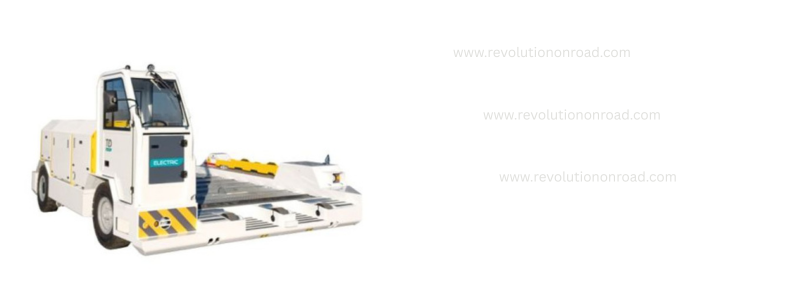

What is a TLD Transporter?

A TLD transporter is a cargo and baggage mover used in airports. It consists of:

· Engine or electric motor (power source)

· Transmission system (for forward/reverse movement)

· Hydraulic system (for lifting/auxiliary operations)

· Electrical control unit (ECU, relays, wiring)

· Braking and safety interlocks

When the transporter doesn’t move, the problem may come from power supply, transmission, hydraulics, or safety systems.

Safety Precautions Before Checking

Key Safety Rules

1. Switch off engine or main power before inspection.

2. Apply parking brakes and use wheel chocks.

3. Wear PPE – helmet, gloves, safety shoes, reflective vest.

4. Keep a fire extinguisher nearby.

5. Never bypass interlocks without controlled testing.

6. Inspect for leaks (oil, fuel, coolant) before touching.

7. Keep the equipment on level ground.

Step-by-Step Troubleshooting Procedure

- Visual Inspection

· Look for error codes or dashboard warnings.

· Check gear lever position.

· Inspect underbody for leaks or broken parts.

- Power Supply & Battery Check

· Measure battery voltage with a multimeter.

· Inspect terminals for corrosion.

· Check main fuse and contactor.

· Ensure emergency stop is released.

- Engine & Fuel System (Diesel Units)

· Verify fuel level and filter condition.

· Check air filter, injectors, and fuel lines.

· Confirm engine oil and coolant levels.

- Transmission & Drive System

· Check transmission oil.

· Inspect clutch, torque converter, or gearbox.

· Inspect drive shaft for damage.

- Hydraulic System

· Verify hydraulic oil level.

· Check for leaks in hoses/cylinders.

· Test pump pressure.

- Parking Brake & Safety Interlocks

· Release parking brake fully.

· Test brake pressure switch.

· Check operator seat switch.

· Inspect door interlock sensors.

- Electrical & Control System

· Test fuses, relays, ECU.

· Verify forward/reverse switch.

· Inspect accelerator pedal sensor.

- Wheels & Mechanical Blockage

· Check brakes for jamming.

· Inspect hub bearings.

· Remove debris under chassis.

Solutions Based on Fault

Electrical & Battery Issues

· Recharge or replace battery.

· Tighten terminals.

· Replace faulty fuses/relays.

Engine Problems

· Clean/replace filters.

· Top up engine oil/coolant.

· Repair injectors.

Transmission Issues

· Replace oil or clutch parts.

· Repair gearbox/drive shaft.

· Calibrate ECU.

Hydraulic Failures

· Top up hydraulic oil.

· Replace hoses/seals.

· Service hydraulic pump.

Safety Interlock Faults

· Reset or replace seat switch.

· Repair parking brake switch.

· Fix door interlock sensor.

Mechanical Blockages

· Free jammed wheels.

· Replace seized bearings.

· Remove obstructions.

Preventive Maintenance Tips

· Daily Checks: fuel, battery, hydraulic oil, brakes, lights.

· Weekly: transmission oil, interlocks, wiring.

· Monthly: ECU diagnostics, lubrication.

· Annual: full engine/hydraulic service, brake overhaul.

· Train operators to avoid misuse.

Conclusion

A TLD transporter not moving can stall airport operations, but with a systematic troubleshooting approach, the problem can be solved quickly. By checking battery, transmission, hydraulics, interlocks, and ECU, you can identify and fix the fault. Most importantly, always follow safety precautions to protect both the equipment and the technician.

Regular preventive maintenance ensures your TLD transporter delivers reliable performance and avoids costly downtime.

I am curious to find out what blog platform you’re utilizing? I’m experiencing some minor security problems with my latest site and I would like to find something more safeguarded. Do you have any suggestions?